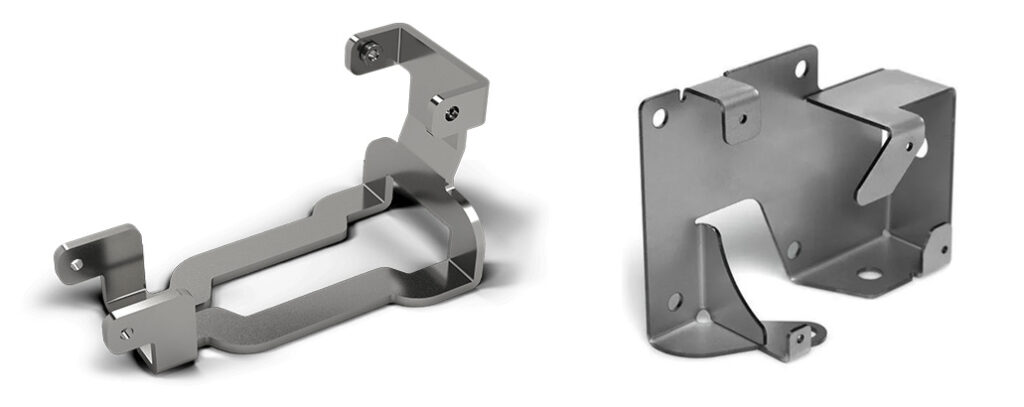

Sheet Metal Fabrication

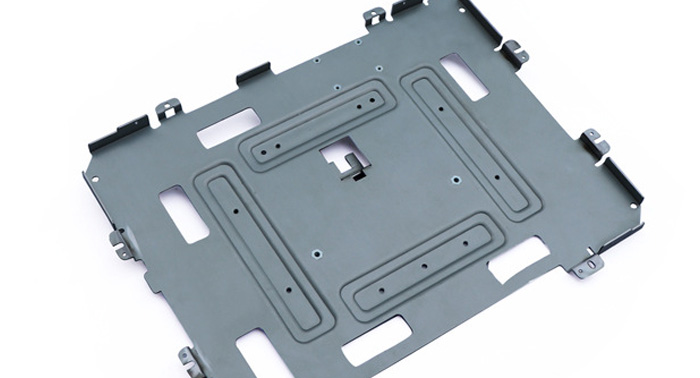

Sheet metal fabrication services encompass the processes of cutting, bending, and assembling sheet metal to create a wide range of products and components for various industries.

Sheet metal thickness 0.5 - 10mm

More than 10 kind of materials and finishes are available

Fastest delivery time 3 working days

Start Get A Quote

All drawings are secure and confidential.

Sheet Metal Fabrication Process

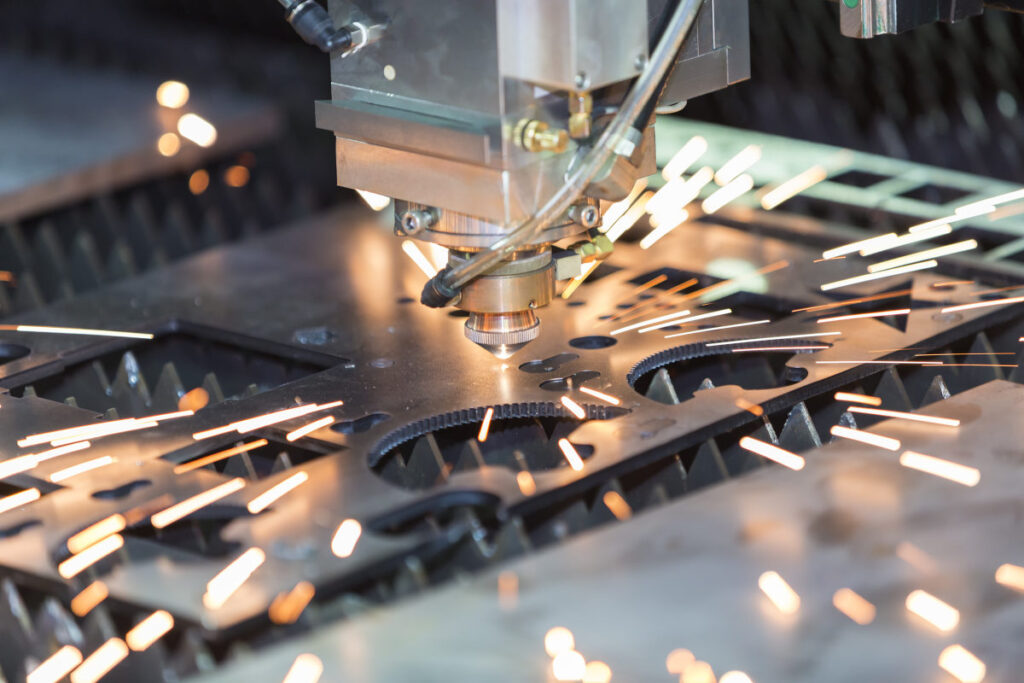

Laser Cutting

Wire Cutting, EDM, CNC Machining, etc

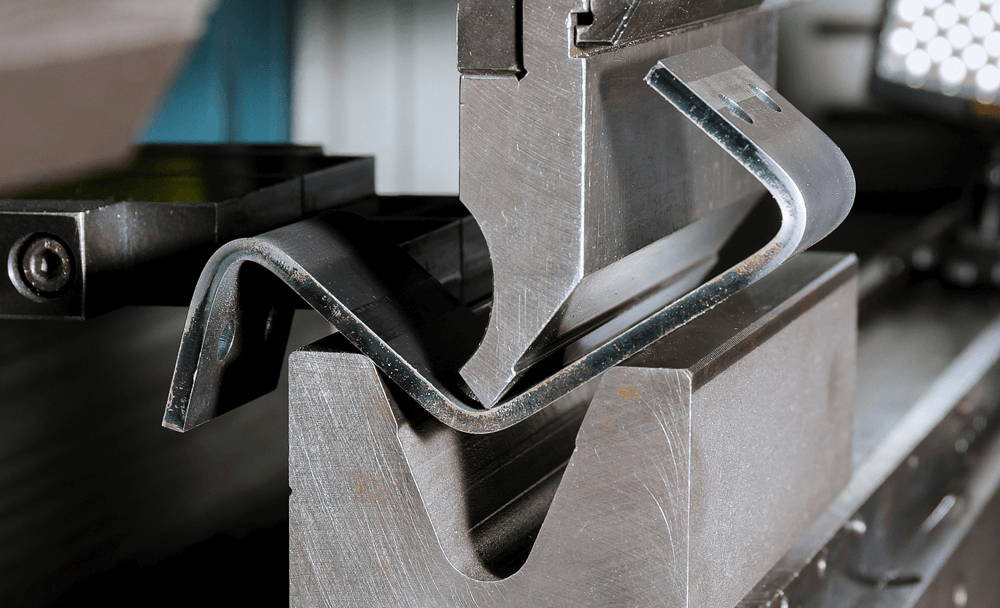

Bending

V-Bending, U-Bending, Multi-angle

Welding

Gas Tungsten Arc Welding, Resistance Spot Welding

Surface Finish

Sandblasting, Anodizing,

Electroplating, Polishing, etc

Sheet Metal Tolerance

If not otherwise specified on the technical drawing, all parts will be machined to ISO 2768 tolerance standards below. Generally you can

choose ISO 2768-m, ISO 2768-f or specify more tighter tolerances in your 2D technical drawings.

Types

Value

Hole sizes

±0.005″

Edge to edge, single surface

±0.010″

Edge to hole, single surface

±0.010″

Hole to hole, single surface

±0.005″

Bend to edge / hole, single surface

±0.015″

Bend to Bend

±0.020″

Edge to feature, multiple surface

±0.030″

Over formed part, multiple surface

±0.030″

Bend anglev

±1°

Sheet Metal Materials

Materials

Subtypes

Aluminum

Stainless Steel

304

Steel Alloy

Brass

Copper

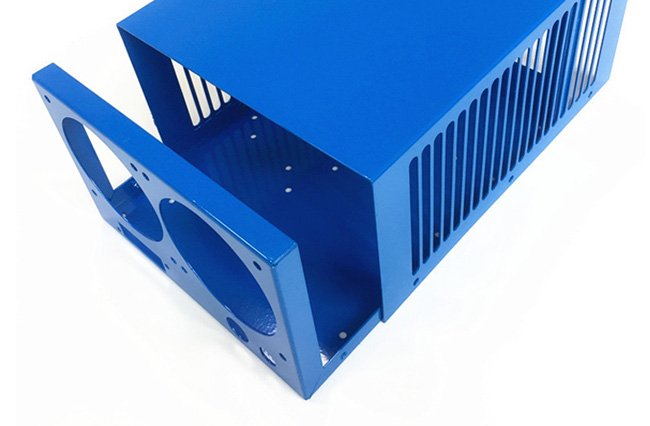

Sheet Metal Surface Finishes

We can instantly quote a wide variety of post-machining surface finishes.

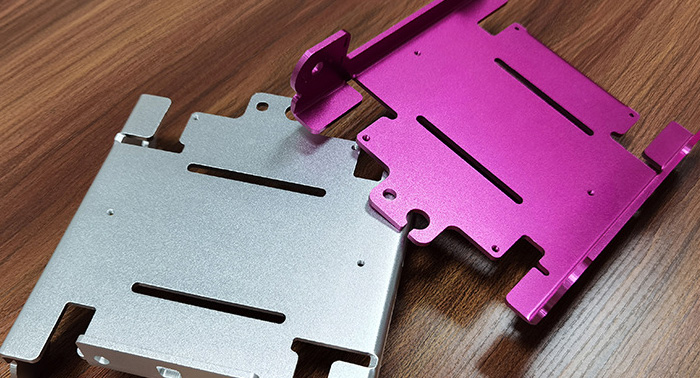

Anodizing

See details

Bead Blasting

See details

Powder Coating

See details

Electroplating

See details

Polishing

See details

Brushing

See details

Alodine

See details

Copper Plating

See details

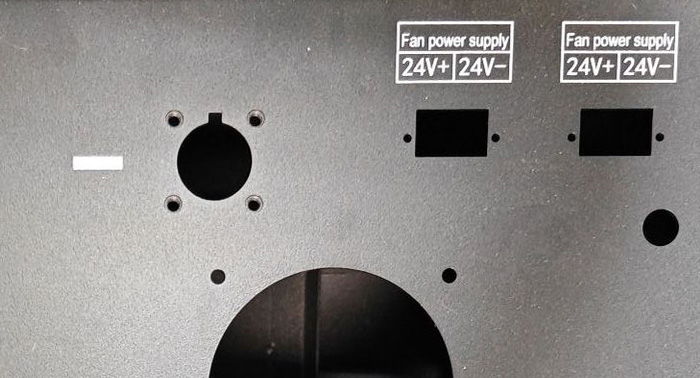

Screen Printing

See details

Chrome Plating

See details

Galvanization

See details

Our Customers speak for us